Product Introduction

Classification and working principle of dust collectors

Mechanical dust collector

Gravity settling chamber: uses the natural sedimentation of dust gravity, with a simple structure but low efficiency, suitable for pre-dust removal of large particles.

Cyclone dust collector: separates particles through the centrifugal force generated by the rotation of airflow, suitable for medium and coarse particles (such as wood chips, mineral powder).

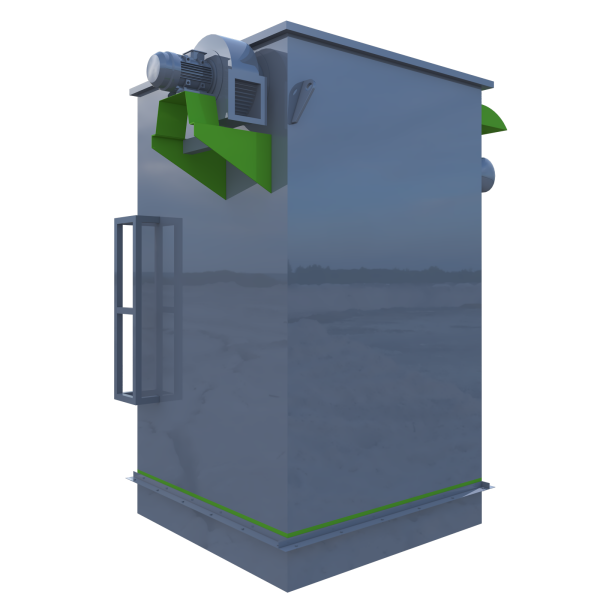

Filter dust collector

Bag dust collector: When dust-containing gas passes through the filter bag, the dust is intercepted, with an efficiency of more than 99%, suitable for fine dust (such as cement, metallurgy).

Cartridge dust collector: similar to the bag type, but uses folded filter cartridges to save space, suitable for light industry.

Electrostatic precipitator

Electrostatic precipitator: uses high-voltage electric field to charge dust and then adsorb it to the plate, suitable for high-temperature and high-humidity flue gas (such as power plants and steel plants).

Wet dust collector

Spray tower/Venturi dust collector: captures dust through water film or droplets, and can simultaneously treat harmful gases (such as chemical and ceramic industries).

New dust removal technology

Composite dust collector: Combine multiple technologies (such as electric bag composite) to improve efficiency.

Nanofiber filter material: Improve filtration accuracy and durability.

Key performance indicators

Dust removal efficiency: Usually required to be >95%, high-efficiency equipment can reach 99.9%.

Processing air volume: Select according to working conditions (such as 1000~100,000 m³/h).

Resistance loss: Affects energy consumption, bag dust collectors are usually 1000~2000 Pa.

Temperature resistance: Electrostatic precipitator can handle flue gas above 300℃, and filter bags need to be selected according to the material (such as PTFE resistant to 260℃).

Application areas

Industry: steel mills (blast furnace gas dust removal), cement plants (kiln head and kiln tail), chemical plants (catalyst recovery).

Energy: coal-fired power plants, waste incineration plants.

Civil: central air conditioning system, workshop air purification.

Selection points

Dust characteristics: particle size distribution, density, viscosity (such as sticky dust requires anti-sticking bag design).

Gas conditions: temperature, humidity, corrosiveness (such as acidic flue gas requires anti-corrosion treatment).

Emission standards: such as China's "Comprehensive Emission Standards for Air Pollutants" (GB 16297-1996).

Maintenance and common problems

Filter bag replacement: Regularly check for damage (usually 2 to 4 years of life).

Cleaning system: Pulse jet pressure needs to be stable (0.2 to 0.6 MPa).

Fault handling: If the dust accumulation on the electrostatic precipitator plate will lead to a decrease in efficiency, it needs to be vibrated and cleaned regularly.