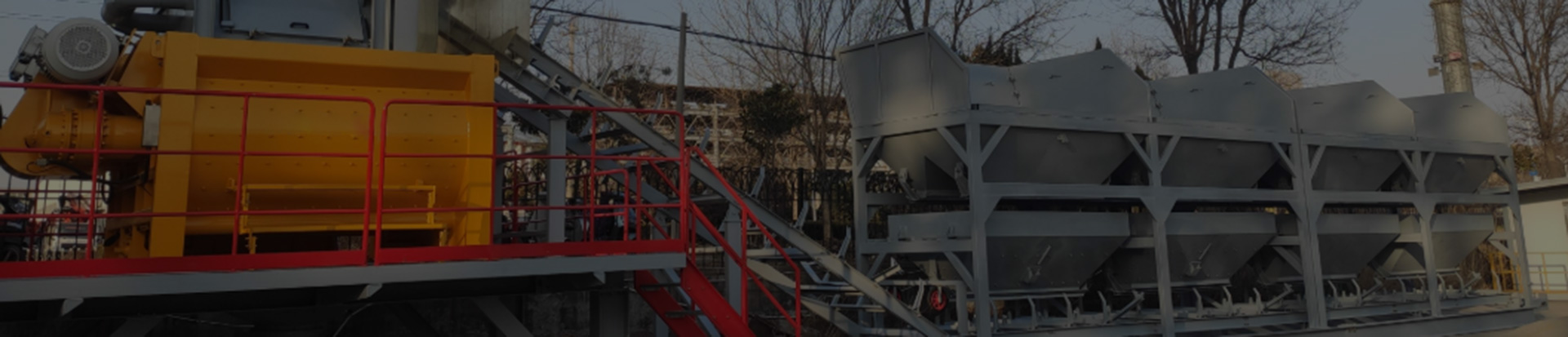

Product Introduction

Main components and working principles:

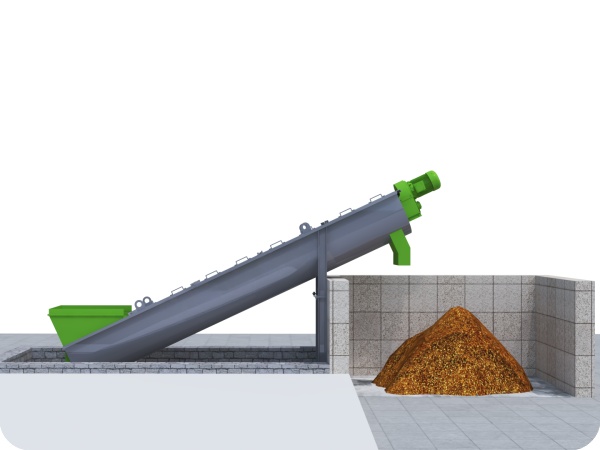

Screw conveying system

The abrasive is transported from the bottom to the blasting wheel or sandblasting area through a spiral shaft (similar to Archimedes' screw) to recycle the abrasive.

Some equipment may use a spiral sorting mechanism to separate reusable abrasives and waste.

Shotblasting/sandblasting system

The high-speed rotating impeller throws the abrasive onto the surface of the workpiece (centrifugal sandblasting) or sprays it with compressed air (air spraying).

Workpiece conveying system

With conveyor belts, rollers or fixtures, ensure that the workpiece passes through the sandblasting area evenly.

Dust removal and recycling system

Filter dust and waste, keep the working environment clean and recycle usable abrasive.

Application scenarios:

Metal processing: remove welding oxide scale, rust, burrs.

Foundry industry: clean the surface sand of castings.

Surface pretreatment: provide roughness for spraying and electroplating.

Glass/stone: etching or matte treatment.

Advantages:

Efficient and continuous operation: suitable for batch processing.

High degree of automation: reduce manual intervention.

Abrasive recycling: reduce costs.