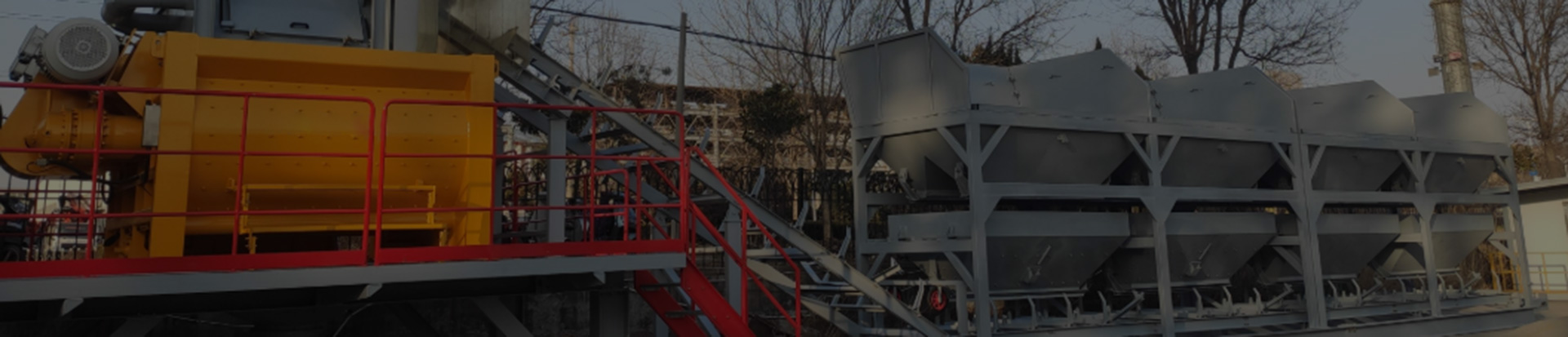

The working principle of a concrete mixing station:

In the construction industry, there is often a fine division of labor and many fine jobs. For example, for mixing powder and sand and gravel, the main thing is to power on the mixer, and then the operation interface is a human-computer dialogue, so that the system can be initialized at the beginning. It mainly includes the volume during production, slump, formula number, etc. In fact, the grade of concrete is also important. In the process of detection, the metering bucket is generally used, and then the various silos, etc. Signals such as full or empty materials can be output, and then for relevant operators, it can also be seen how the mixing program is controlled.

The concrete mixing station needs to open the butterfly valves of the cement tank and fly ash, and start the spiral motor. This is how to transport fly ash, and then open the water tank, and let the metering bucket flow into the admixture and water. After metering, the requirements are set, and then the bucket door in the metering bucket is opened. If some ingredients are input into the mixer, and then mixed and stirred, it will bring benefits to people. This is basically the working principle of this aspect. Specifically, the workmanship in this aspect is becoming more and more refined and has been rapidly developed. People love such concrete.

Concrete mixing stations have obviously brought certain conveniences to people in the construction industry. The main reason is that it is a good process that can have a good impact on people. Now, this aspect has a good development prospect. It will be able to develop better and better in the future and bring great help to people.