Product Introduction

Core functions of vibrating screen

Classification: Separate materials by particle size (such as coarse, medium and fine particles).

Screening: Remove impurities or unqualified particles (such as grain impurity removal and ore sorting).

Dehydration/de-sludge: Separate solids and liquids (such as sand washing and coal slime treatment).

Solid-liquid separation: Filter solid particles in slurry (such as chemical raw material filtration).

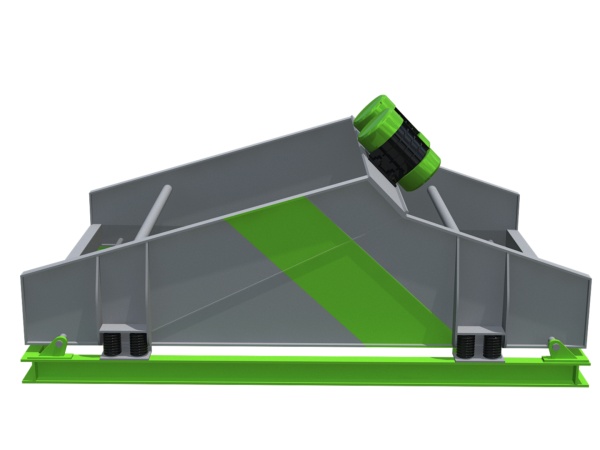

Key structures and components

Screen box: Carrying screen and material, need to be wear-resistant (commonly used stainless steel or carbon steel).

Screen: determines the screening accuracy, and the materials include wire mesh, polyurethane, nylon, etc.

Vibration motor/exciter: power source, adjusting the amplitude and frequency can change the screening effect.

Shock-absorbing spring: rubber spring, steel spiral spring, etc., to reduce the vibration transmitted to the foundation.

Support frame: fix the screen body to ensure stability.

Selection points

Material characteristics:

Particle size distribution, moisture content, viscosity, corrosiveness (such as acidic materials require stainless steel screens).

Screening requirements:

Processing capacity (tons/hour), screening efficiency (such as 95% pass rate), number of screen layers (single layer or multi-level classification).

Working environment:

Explosion-proof (chemical), food grade (304/316 stainless steel), high temperature resistant (such as foundry industry).

Special requirements:

Sealed and dustproof (pharmaceuticals), silent design (urban construction), automated connection (assembly line).

Common problems and solutions

Screen blockage:

Reason: material is wet or electrostatically agglomerated.

Solution: Use ultrasonic screen cleaning device or bouncing ball screen cleaning design.

Low screening efficiency:

Reason: amplitude/frequency mismatch or unreasonable screen mesh.

Solution: Adjust vibration parameters or replace screen.

Abnormal vibration of equipment:

Reason: eccentric block of vibrator is loose or bearing is damaged.

Solution: Tighten bolts or replace bearings.

Maintenance and care

Daily inspection: whether the screen is damaged or the bolts are loose.

Regular lubrication: Add high-temperature lithium-based grease to the vibrator bearing every 3 months.

Cleaning: Clean residual materials after shutdown (especially in the food industry).

Screen replacement: Replace in time according to wear and tear to avoid affecting accuracy.

Technology development trend

Intelligence: Install sensors to monitor vibration status and predict faults (such as remote monitoring of the Internet of Things).

Modular design: Quickly replace the screen or vibration unit to reduce downtime.

Energy saving and environmental protection: low power consumption motor, noise reduction technology (such as rubber shock pads).

Example application scenarios:

Mines: Circular vibration screening for iron ore selection (particle size 20-100mm).

Food factory: Rotary vibration screen for flour screening (mesh size 100-200 mesh).

Wastewater treatment: Linear screen for dewatering sludge (processing capacity 50t/h).