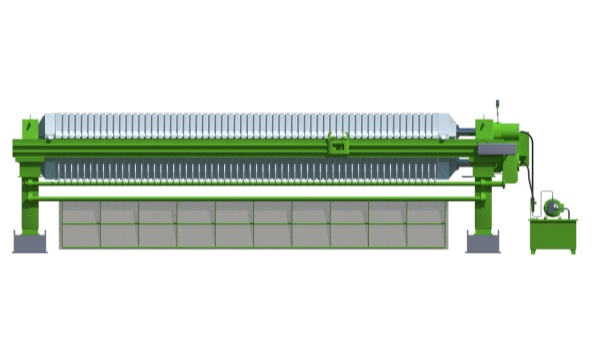

Product information

Core functions and features

Efficient dehydration: The pressure can reach 0.4-2.0MPa, significantly reducing the moisture content of the filter cake (such as the moisture content of the pulp after dehydration can be reduced to 15%-25%).

Flexible regulation: Adapt to different material characteristics by adjusting the pressure and filtration time.

Environmental protection and energy saving: Compared with centrifuges, it has lower energy consumption and no dust risk.

Key components and functions

Filter plate/filter frame:

Material: polypropylene (PP), reinforced nylon, stainless steel (corrosion resistant).

Structure: open flow (visible filtrate discharge)/undercurrent (closed pipeline).

Filter cloth:

Selection basis: acid and alkali resistance (such as polyester), temperature resistance (such as polypropylene ≤90℃), air permeability (mesh number).

Hydraulic system:

Provide compression force (usually 10-20MPa), electric hydraulic pump or manual operation.

Control system:

Fully automatic programmable PLC control, realizing the whole process of compaction-feeding-washing-unloading.

Core parameters of model selection

Processing capacity: calculated according to the volume of the filter chamber (L) and the cycle (times/hour).

Filtration pressure: generally 0.6-1.6MPa, and the diaphragm pressing stage can reach 2.0MPa.

Filter cake moisture content: diaphragm filter press is 5%-10% lower than ordinary chamber type.

Special requirements: explosion-proof (chemical industry), high temperature resistant (ceramic industry), aseptic (food grade 304 stainless steel).

Workflow (taking automatic chamber type as an example)

Press the filter plate: the hydraulic cylinder pushes the filter plate to form a closed filter chamber.

Feed pumping: the slurry passes through the filter cloth under pressure, and the solids are intercepted to form a filter cake.

Washing/drying (optional): replace the residual filtrate with clean water or blow with compressed air.

Discharging: Pull the filter plate apart, and the filter cake will fall off automatically (with the aid of a vibrator if necessary).

Common problems and solutions

The filtrate is turbid:

Reason: The filter cloth is damaged or the mesh size does not match.

Solution: Replace the filter cloth or add a pre-coat (such as diatomaceous earth).

The filter cake is not formed:

Reason: Insufficient feed pressure or too fine material particles.

Solution: Increase pump pressure or add flocculants (such as PAC).

Filter plate leakage:

Reason: Sealing surface wear or uneven clamping force.

Solution: Repair the sealing surface or recalibrate the hydraulic system.

Maintenance and optimization

Daily maintenance:

Cleaning the filter cloth (backwashing or ultrasonic cleaning), checking the hydraulic oil level.

Key life parts:

Filter cloth (3-6 months), filter plate (3-5 years), hydraulic seal (1-2 years).

Energy efficiency optimization:

Use variable frequency pump to reduce power consumption, and waste heat recovery to dry the filter cake.

Cutting-edge technology

Intelligent:

Integrated pressure sensor and AI algorithm to optimize filtration cycle in real time (such as Endress+Hauser solution).

New material filter plate:

Carbon fiber reinforced composite material (lightweight + corrosion resistance).

Zero emission design:

Combined with steam drying to achieve full drying of sludge (water content <5%).