Product Information

Core functions and features

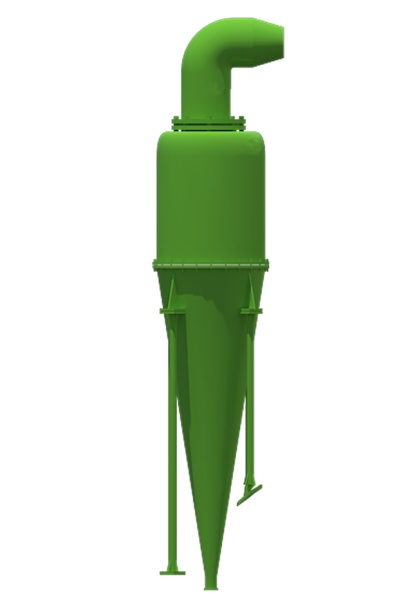

Separation principle: Through tangential feeding, a high-speed rotating flow field is generated, and centrifugal force is used to separate particles of different densities or particle sizes.

Core advantages:

No power consumption (only relying on fluid pressure energy)

Fast processing speed (single unit processing capacity can reach more than 100m³/h)

Multi-stage series connection can be used to improve separation accuracy

Typical applications:

Slurry classification (such as gold and iron ore)

Wastewater treatment (sand removal, oil-water separation)

Chemical industry (catalyst recovery, crystallization separation)

Key structures and working principles

(1) Core components

Feed port: tangential feeding to form a vortex (pressure usually requires 0.1-0.4MPa).

Cone: The angle (10°-20°) affects the separation accuracy. The longer the cone section, the better the fine particle separation effect.

Overflow pipe: discharge light phase or fine particles (top).

Underflow port: discharge heavy phase or coarse particles (bottom, the opening can be adjusted to control the discharge concentration).

(2) Separation process

Tangential feeding: The slurry rotates at high speed, generating centrifugal force (up to hundreds of times the gravity).

Classification/separation:

Coarse particles/high-density objects move toward the outer wall and are discharged from the bottom flow port.

Fine particles/low-density objects migrate toward the center and overflow from the overflow pipe.

Parameter control: Optimize the separation effect by adjusting the feed pressure and bottom flow diameter.

Maintenance and optimization

Regular inspection: Wear of the inner wall of the cone and changes in the size of the bottom flow port.

Wear-resistant measures: Ceramic/rubber lining (the service life of mining applications can be extended by 3-5 times).

Intelligent control: Install pressure sensors and automatic valves to adjust the bottom flow opening in real time.

Technology frontier

Microcyclone: used for nanoparticle separation (such as graphene purification).

CFD simulation optimization: Design efficient flow fields through fluid dynamics simulation.

Compound cyclone: Combined with gravity sedimentation (such as cyclone-sedimentation all-in-one machine).