Product Information

Main types

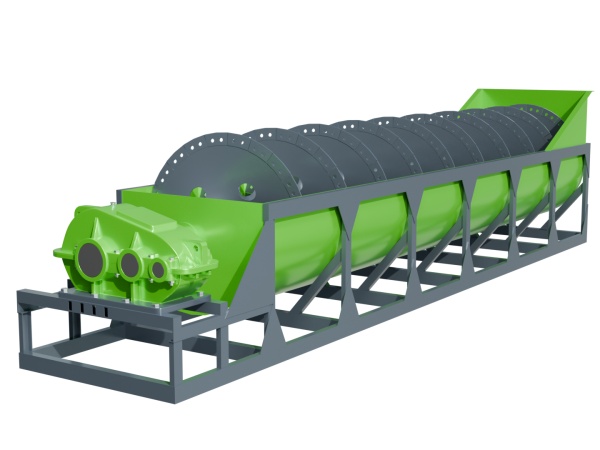

Drum stone washer: The drum rotates to make the stones rub against each other, and water is sprayed to wash at the same time, which is suitable for small and medium-sized stone cleaning.

Vibration stone washer: It uses a combination of vibration screening and high-pressure water, with high cleaning efficiency, suitable for stones with uniform particles.

Spiral stone washer: The spiral blade pushes the stone forward, and it washes while conveying, which is suitable for sand, gravel and other materials.

High-pressure water gun stone washer: Manual or semi-automatic operation, for large or special-shaped stones (such as landscape stones).

Working principle

Feeding: The stone is put into the stone washer through a conveyor belt or manually.

Cleaning: The water spray system (high-pressure water or circulating water) rinses the surface, and the mechanical brush or drum friction removes stubborn stains.

Separation: The sewage and impurities are separated by a screen or sedimentation tank, and the clean stone is discharged.

Dehydration: Some equipment is equipped with a dehydration screen to reduce the moisture content of the stone.

Application scenarios

Construction industry: cleaning of concrete aggregates, gravel, machine-made sand, etc.

Decorative stone: pre-treatment of marble, granite and other surfaces before polishing.

Garden engineering: cleaning of landscape stones and pebbles.

Mining: preliminary cleaning of ore to improve grade.

Advantages and characteristics

Efficient cleaning: mechanized operation is several times faster than manual cleaning.

Water-saving design: some equipment is equipped with a water circulation system to reduce waste.

Customizable: adjust the cleaning intensity according to the size and hardness of the stone.

Environmental protection: sedimentation tanks or filtration systems reduce sewage discharge.

Purchase precautions

Stone type: hardness and size determine the equipment model (such as soft limestone requires gentle cleaning).

Capacity requirements: select small (1-5 tons/hour) or large (more than 50 tons) equipment according to output.

Water source and environmental protection: circulating water models can be selected in water-scarce areas, which must meet local environmental protection standards.

Maintenance cost: Check whether wearing parts (such as brushes and screens) are easy to replace.

Maintenance and care

Clean the sedimentation tank regularly to prevent blockage.

Check whether the nozzle and screen are worn.

Bearings, gears and other parts need to be lubricated.

Empty the water tank during long-term shutdown to prevent rust.