Product Introduction

Main types of cement tanks

(1) Classification by structure

Vertical cement tank:

Common capacities: 30T, 50T, 80T, 100T, 200T, etc.

Features: Small footprint, suitable for fixed mixing plants or long-term storage.

Horizontal cement tank:

Suitable for sites with limited space, can be placed horizontally, but the capacity is generally small (20T~50T).

(2) Classification by unloading method

Pneumatic conveying: Cement is fluidized by compressed air and transported through pipelines (high degree of automation, suitable for large mixing plants).

Screw conveying: Unloading with screw conveyor (low cost, suitable for small and medium-sized projects).

(3) Classification by material

Carbon steel cement tank: Economical and practical, requires anti-corrosion treatment.

Stainless steel cement tank: Strong corrosion resistance, suitable for humid or corrosive environments, but high cost.

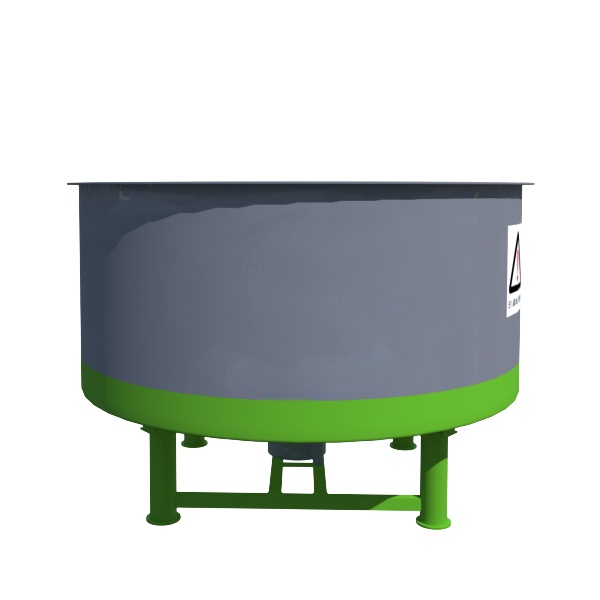

The main structure of cement tank

Tank: cylindrical or conical structure, usually welded from steel plates.

Legs/brackets: support the entire tank to ensure stability.

Feed port: open at the top for loading cement (can be connected to bulk cement trucks).

Discharge port: conical design at the bottom to facilitate cement flow, connected to screw conveyor or pneumatic conveying system.

Dust removal system (pulse dust collector/bag dust collector): prevent dust pollution.

Level meter (high and low level sensor): monitor cement inventory to prevent overflow or empty warehouse.

Arch breaking device (vibration motor/pneumatic arch breaking): prevent cement caking and blockage.

Application scenarios of cement tank

Concrete mixing station: store raw materials such as cement and fly ash.

Dry mortar production line: used for powder storage in mortar formula.

Construction site: temporary storage of bulk cement to reduce the loss of bagged cement.

Power plants and chemical plants: storage of fly ash, mineral powder and other industrial powders.