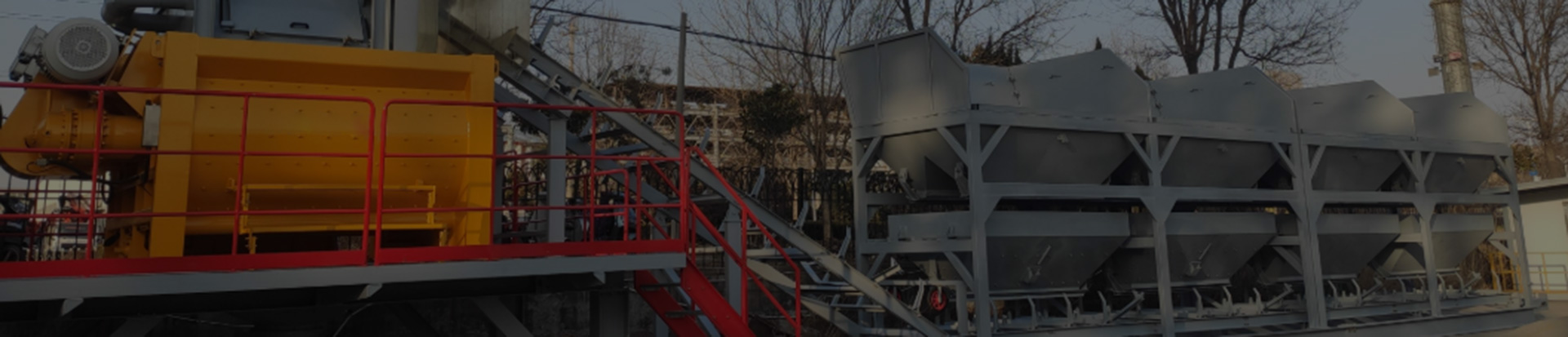

Product Introduction

Equipment performance characteristics and advantages

YX6000 spiral sand and gravel separator: This separator is a new product jointly designed and developed by our company's researchers based on the absorption of advanced technologies at home and abroad, combined with the actual situation in our area. This device is mainly used for cleaning the mixer truck in concrete mixing plants and separating the sand, gravel, and water (cement) from the remaining waste concrete. It solves the pollution problem of waste concrete, realizes the recycling and reuse of sand, gravel, water, etc., and to a certain extent saves the production cost of mixing plants on the basis of green environmental protection.

The technical features of this product are compact layout, small footprint, and effective reduction of equipment wear and tear through technical means, increasing equipment service life. The bottom support adopts specially designed long-life bearings; The reducer is selected from the Sino Australian joint venture brand - Ausson Jianglang; The spiral is made of wear-resistant steel with a height of 500, and the bottom of the spiral is designed with mixing blades. The concrete poured into the discharge port of the whole vehicle can also be easily separated; By increasing the load-bearing and separation capacity of the separator, high-density concrete content can also be easily separated; These designs greatly reduce equipment maintenance time and costs.

Technical Parameters

Name | Parameters (single parking space) (110,000) | Parameters (double parking space) (120,000) |

Separation capacity | ≥30t/h | ≥40t/h |

Installed power | 12.5Kw | 14.5kw |

Dimensions | 8300×2000×3550 | 10300×2000×3550 |

YX6000 Spiral Separators Configuration Table |

Name | Specifications/Features | Unit | Quantity | Supporting Manufacturers | Remark | |

Separator host | motor | YE3-132S-4 | set | 1 | Odson Jianglang (Sino-British joint venture) | supporting equipment |

reducer | CPZH54B-50-5.5 | |||||

cabin | 16Mn-t6 | YX Homemade | ||||

Spirochete | NM500-t8 | |||||

outriggers | [12# | |||||

Discharge hopper | [12#-t3 steel plate | |||||

Hopper guard net | Standard | |||||

Flushing components | DN65 galvanized pipe | |||||

Water pumps and components | Submersible slurry pump | 65ZJQ20-20-4 | tower | 2 | Runquan Pump Industry | |

Pump connection kit | Standard | set | 2 | YX Homemade | ||

Water pump hanger | Standard | set | 2 | YX Homemade | ||

Hand chain hoist | 1T | tower | 2 | male elephant | ||

Water pump frame | Standard | indivual | 2 | YX Homemade | ||

pipe fittings | Water pipe | DN65 galvanized pipe | rice | several | YX Homemade | Determined according to the plan |

flushing tube | DN65 galvanized pipe | rice | several | YX Homemade | ||

pipe fittings | DN65 | indivual | several | YX Homemade | ||

electrical system | Controller | PLC | tower | 1 | Siemens | |

AC contactor | LC1D Series | tower | 5 | Schneider | ||

Motor circuit breaker | GV2ME Series | tower | 5 | Schneider | ||

Molded case circuit breakers | 125A, etc. | tower | 1 | Schneider/Chint | ||

Buttons/knobs | indivual | 3 | Schneider/Chint | |||

indicator light | indivual | 3 | Schneider/Chint | |||

control cabinet | Stainless steel waterproof type | indivual | 1 | YX | ||

Intermediate relay | 220V | set | 1 | Schneider/Omron | ||

warning light | indivual | 1 | Formosa Plastics Corporation | |||

Cables | National Standard | rice | several | Green Light | ||

appendix | National Standard | indivual | several | YX | ||

Button box assembly | Cabinet | 300*200 | indivual | 1 | YX | |

Button | indivual | 2 | Schneider/Chint | |||

bracket | indivual | 1 | YX Homemade | |||

Lubrication system | Automatic lubrication pump | 220V | tower | 1 | Rongxing Technology | |

Lubrication pipe | Standard | set | 1 | Rongxing Technology | ||

Cables | cable | 3*2.5 | rice | 30 | Green Light | Determined according to the plan |

appendix | appendix | set | 1 | YX | ||

Note: The specifications/features, quantities, etc. listed in the table are standard configuration related parameters, and actual parameters may change due to changes in specific plans. As a component of zero sewage discharge, the electrical system is uniformly deployed in the zero sewage discharge control system. | ||||||