Industry Challenge

For decades, traditional agitators in batching plants have delivered suboptimal performance. Common failures include rapid sludge accumulation, severe tank bottom solidification, and extensive wall scaling within mixing pits. These issues necessitate frequent manual cleaning, disrupting plant operations, increasing costs, and creating significant operational burdens. This persistent problem represents the most critical pain point for concrete producers.

Our Solution

Addressing these challenges, our R&D team committed to developing an agitator that:

Enhances mixing efficiency

Minimizes sludge settlement & wall adhesion

Delivers energy-saving & environmental benefits

After one year of intensive development, iterative testing, and technical refinement, we engineered the revolutionary Pressure-Flow Wastewater Agitator.

Technical Specifications & Key Features

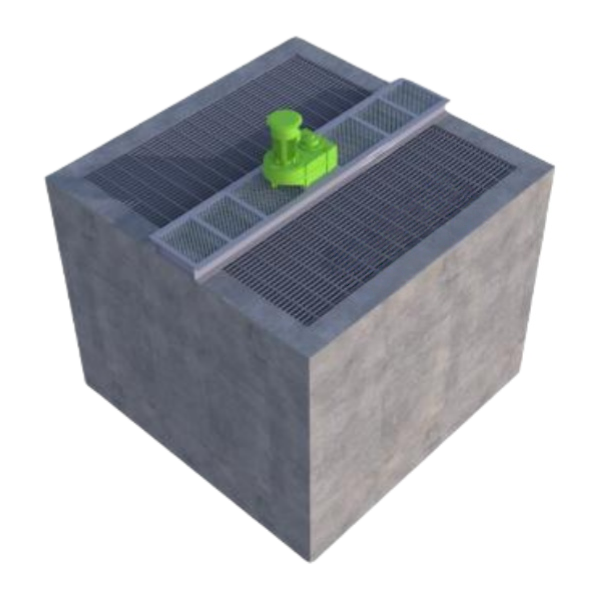

The blades are uniquely designed, capable of sucking and pressing liquids. When the blades rotate, the sewage is pressed from the top downwards to the bottom of the sewage tank, causing the sewage to roll outwards from the bottom upwards without any dead corners. It stirs in a boiling state, allowing the sediment at the bottom of the tank to adhere to the tank walls and settle down, stirring them at the fastest speed to become uniform. The sediment particles are evenly suspended in the sewage, no longer solidifying, settling, or adhering to the tank walls, truly achieving the effect of eliminating the need for tank cleaning.

The mixers are all equipped with gear-type reducers (F series). Although they are powered by a 5.5KW motor, they can still output powerful force. The reducer's rotational speed can reach 92 revolutions per minute. Due to the high mixing speed, the mixers can achieve the goal of short mixing time and long intermittent time, effectively reducing energy consumption. After comparison and calculation, installing three of our three-phase flow sewage mixers per year can save over 140,000 yuan in electricity costs.

The company uniformly equips high-maintenance slag pump. The bottom of the pump is equipped with alloy stirring teeth, which have the functions of stirring, crushing and anti-blockage. This slag pump is a customized product of our company. It operates stably and has a high wear resistance coefficient.

Technical Parameters

Item | YX 1300J Slurry Agitator | Unit | Qty | |

Agitator | Motor Power(Replaceable) | 5.5KW (YE3-132S-4) | Set | 1 |

Reducer | CPFS44B18-132SH-G-L5 | |||

Agitate Shaft | ¢85 | |||

Agitate Blade (Mixing Pool) | 1300mm | |||

Agitate Blade (Mixing Tank) | 1500mm | |||

Rotation Speed | 92r/min | |||

Brackets | Steel Brackets | 14# | Set | 1 |

Protective Steel Net | Standard | 1 | ||

Electric System | AC Contactor | NXC Series | PC | 1 |

Motor circuit breaker | NS2 Series | PC | 1 | |

Controller | JSS48A-S200/SMART | PC | 1 | |

Cable | Cable | 3*2.5+1 | Meter | 15 |

Accessory | Set | Several | ||