The main part of the sand and gravel separator during operation is its separation system. Only with a good separation system can you have a good separation effect during use, and you can also flexibly adjust it during use.

The surface of the sand and gravel separated by the equipment is relatively clean without a lot of sludge, and the ash content in the sand is also relatively small. Because of the good separation effect, the water content is also relatively small, and the water in it can be recycled, which can well make the sewage reach a zero discharge effect; and the equipment itself is also very good and easy to operate.

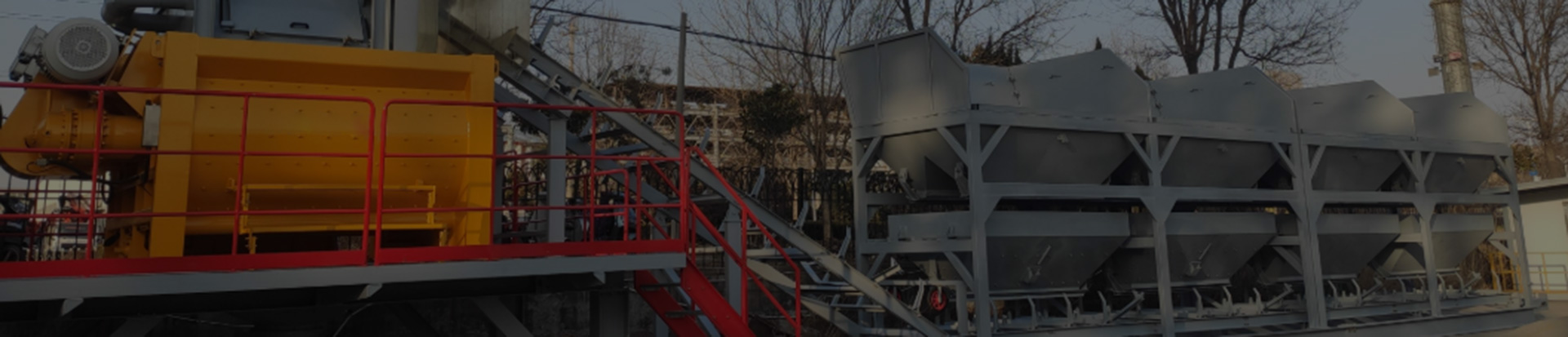

Among the separation equipment, the row hole type equipment can currently achieve a better treatment effect, and it needs to be used in conjunction with the stone sweeper and the photoelectric control system. The sand and gravel separator is mainly used to separate and recover concrete, sand, water, etc. for reuse during operation. The equipment can deal with the problems caused by concrete pollution very well when it is used, and it will also save more resources when it is used. In addition, when using it, in addition to separating and cleaning the concrete, the separated sand, stone, water, etc. can be reused. The remaining sewage will be deposited after being treated in the three-stage sedimentation tank, and then the clean water will enter the circulation in the machine again.