What small details should be paid attention to during the debugging of concrete sand and gravel separator? During the installation and debugging of the equipment, details cannot be ignored. Once some details have problems, it will often affect the normal use of the entire equipment.

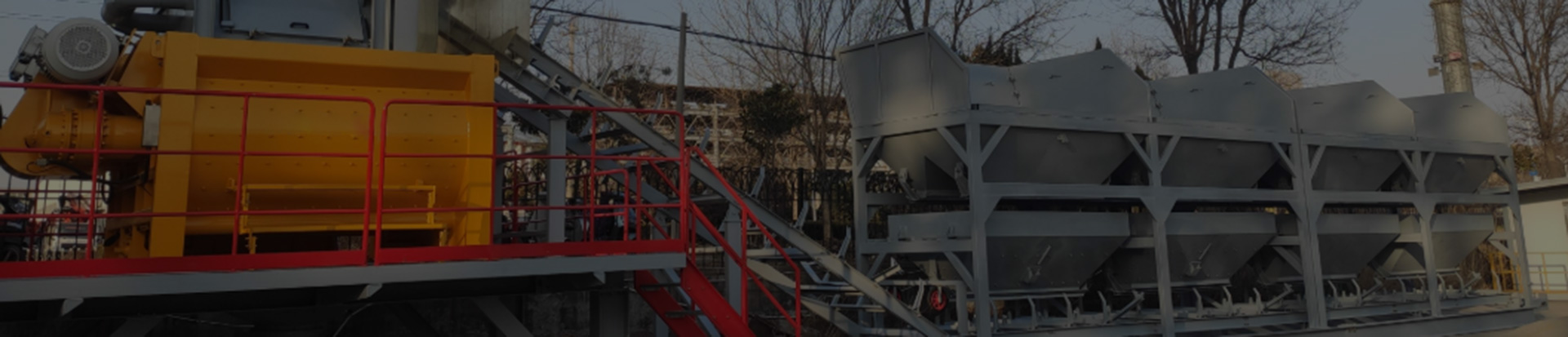

First of all, the concrete sand and gravel separator has a relatively large equipment twist, so the machine should be installed on the concrete foundation. At the same time, embedded weldments should be installed on the foundation to facilitate welding during installation.

Secondly, the foundation depth and area are calculated separately according to the soil conditions. Enpu recommends that the foundation weight is roughly 3 times the weight of the machine, and the machine installation size refers to the actual measurement data. After installation, the construction technicians should check whether the reducer gears are displaced, whether the gap between the water tank and the large wheel bucket is consistent, etc., and fix the machine on the foundation after adjustment.

In addition, add lubricating oil and adjust the height of the oil level. This height is generally 50% below the center of the shaft. After the installation and adjustment of the concrete sand and gravel separator, it is necessary to conduct a trial run. At this stage, the no-load test run of the equipment should reach - continuous operation for two hours; all fasteners must be firm and not loose; reducer. Now many of the transport vehicles in the mixing station are social vehicles, and the mobility of personnel is relatively large, which makes the management of our mixing station more difficult. They only care about making more trips to earn more freight, but do not follow the regulations for cleaning the mixer truck discharge, resulting in blockage, resulting in unclean discharge of the tank, and the material is accumulated in the tank. In the absence of special care, the lumps are difficult to clean in the tank, and the sand and gravel separator cannot work normally.

If there is leftover material in the mixer truck, if the driver still follows the original set procedure, it is easy to cause blockage and even damage to the separator equipment, because the original set procedure is for normal transportation. If the cleaning time is shortened, such as only cleaning for 10 minutes, it is obviously impossible to meet the requirements for cleaning and separation of leftover materials!