Product Information

Main Technical Parameters of YXSS60 Concrete Mixing Station

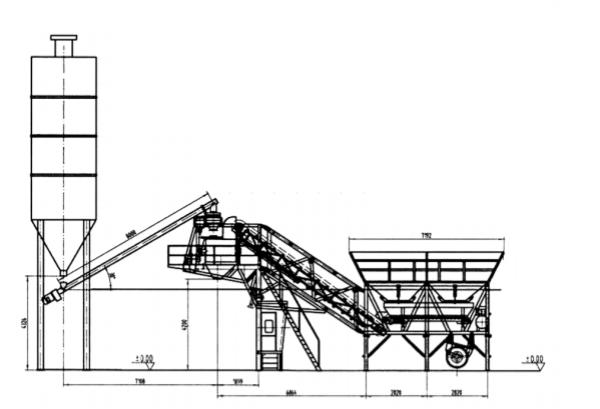

Parameter Name | Model | YXS60 |

Complete Plant Part | Maximum Capacity | 60M³/H |

Discharging Height | 4M | |

Working Cycle Time | 60S | |

(Overall Dimension | 37000×14000×10828MM | |

Total Power | 105KW | |

Concrete Mixer | Concrete Mixer Model | JS1000 |

Aggregate Batching Machine | Aggregate Batching Machine Model | PLD1600 |

Pneumatic System | Air Compressor Model | V-0.67/10 |

Rated Discharge Pressure | 1.0MPa | |

Air Discharge Quantity | 0.67M³/Min | |

Motor Power | 4KW | |

Weighing System | Weighing Precision of Aggregate | ±2% |

Weighing Precision of Cement | ±1% | |

Weighing Precision of Water | ±1% |

Main types and selection suggestions

Classification by movement mode

Trailer Forced twin-horizontal or vertical shaft mixer to ensure concrete uniformity (common capacity: 0.5m³~2m³/dish) type (economic type):

Requires truck towing, suitable for flat sites (such as rural road construction).

Representative models: HZS25 (25m³/h), HZS35 (35m³/h).

Self-propelled (high-end type):

Integrated power system, can move by itself over short distances (such as crawler mixing plants).

Suitable for mines and rugged terrain (such as Cemix MC series).

Application scenarios and advantages

Typical applications

Highway/railway construction: Move with the progress of the project to reduce the distance of concrete transportation.

Post-disaster reconstruction: Quickly deploy to disaster areas to provide concrete.

Rural housing construction: Eliminate fixed station investment and reduce costs.

Military engineering: Rapid field construction to support military infrastructure construction.

Core advantages

Quick transfer: can be disassembled and transported to the new site within 1 day.

Cost saving: no need to harden the foundation, reducing civil engineering investment.

Environmental compliance: closed design + dust removal system to meet environmental protection requirements.

Intelligent control: recipe storage, fault alarm, data recording function.

Common problems and maintenance

(1) Common faults

Inaccurate batching: check whether the sensor is calibrated to avoid the influence of aggregate moisture content on weighing.

Mixer jam: clean the agglomerated concrete regularly, especially before shutting down.

Structural deformation during movement: fix the legs and mixer main unit during transportation to avoid bumpy damage.

(2) Daily maintenance

Lubricate the agitator shaft and conveyor belt bearings daily.

Clean the dust collector filter element weekly to prevent clogging.

Empty the water tank and gas tank during long-term shutdown to prevent rust.