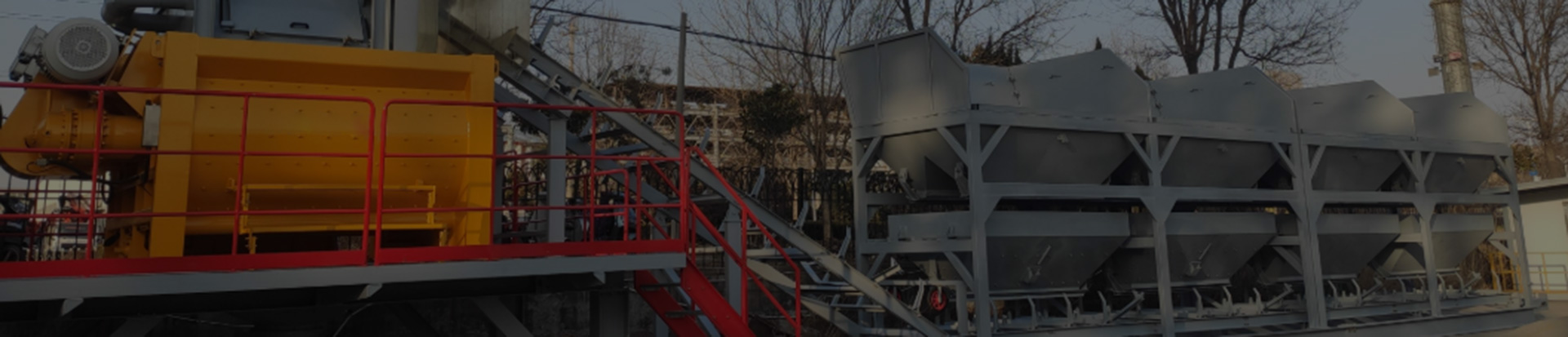

Product Introduction

Equipment performance characteristics and advantages

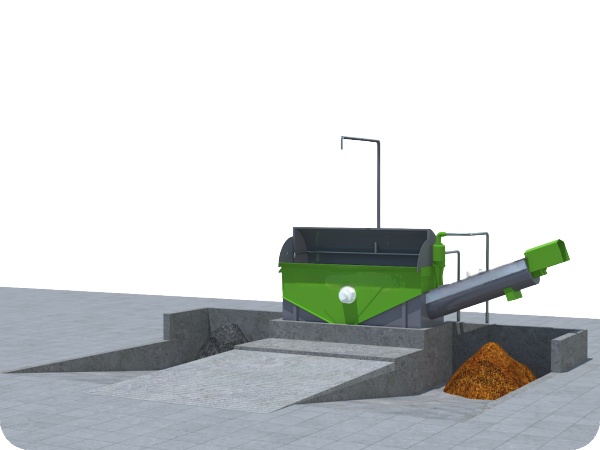

YX60 vibrating sand and gravel separator (eccentric shaft type): It is a product specially designed by our company for the recycling of concrete sand and gravel in the concrete industry. The industry standard for the inspection of this equipment is "Recycled Light and Coarse Aggregates from Construction Waste for Concrete" (Plan No. 2020-0457T-JC).

At present, the vibrating screen sand and gravel separator generally adopts a vibrating motor type, which is equipped with a vibrating motor of about 1.5KW on each side of the front and rear of the separator. This determines the upper limit of the vibration source power. When this separator works, only two vibrating motors vibrate regularly, and the sand and gravel are allowed to slide down freely by the inclined angle of the vibrating screen. If a large amount of concrete is poured into the sieve at the same time, it will inevitably cause sand and gravel accumulation, affecting the normal operation of the separator. Therefore, this equipment has limitations in use and design defects.

Our eccentric shaft vibrating sand and gravel separator has a fundamentally different design from others. This sand and gravel separator adopts an eccentric shaft design, which means that the motor drives the eccentric shaft to rotate, and the convex concave curve of the eccentric shaft drives the screen mesh to swing up, down, left, and right greatly, just like the movement of a dustpan, which disperses the sand and gravel poured into the screen mesh and shakes it in the direction of the stone bin. Even if the whole vehicle concrete is poured into the vibrating screen, it can instantly disperse and smoothly fall into the stone bin; This design is based on the vibration principle of the separation equipment between the stone carving factory and the sand and gravel factory. The vibration amplitude is large, the equipment operates stably, is sturdy and durable, and has strong sustainability; In addition, this separator screen adopts imported polyurethane design, high elasticity, narrow mesh at the top and wide mesh at the bottom, completely preventing filter blockage. If the screen blockage occurs under normal use, we will compensate the customer for all losses. This polyurethane material screen is currently only used by our company in China, which is also the reason why this sand and gravel separator has strong market competitiveness.

The screening capacity of YX60 vibrating sand and gravel separator is ≤ 60T/H, which can meet the separation task of 50 tank trucks in the mixing plant; The size of the stone separation is greater than or equal to 5mm, and the size of the sand separation is less than or equal to 5mm; The control system meets the functions of fully automatic, manual, and one key start; It is an essential concrete recycling and environmental protection equipment for concrete mixing plants.

Technical Parameters

Model | YX60(single-unit) | Screening Capacity | ≤60T/H |

Overall dimensions (MM) | 6500*1800*2500 | Total Power | 13KW |

Number of Mixer Trucks | ≤50units | Total Weight(KG) | 6500KG |

Stone size division | ≥φ5mm | Sand size division | ≤φ5mm |

Configuration of YX60 vibrating separator

Name | Specifications / Features | Unit | Quantity | Supporting Manufacturer | Notes | |

Vibration material trough section | Material tank body | T4-T8 | Set | 1 | YX and Homemade | |

Eccentric drive shaft | EQ140-L | YX and Homemade | ||||

rack | 140x80 | YX and Homemade | ||||

sieve plate | Polyurethane 6*4mm | Imported from Germany | ||||

Rinse tube group | Galvanized pipe | YX and Homemade | ||||

spring | 18x190x95 | number | 8 | YX and Optimal Selection | ||

electrical machinery | YE2-160M-6-7.5 | Unit | 1 | YX and Optimal Selection | ||

Sand removal machine section | CYCLOIDAL REDUCER | BLD4-59-7.5 | set | 1 | YX and Optimal Selection | |

motor | YE2-132M-4-7.5 | YX and Optimal Selection | ||||

structure | T6 | YX and Homemade | ||||

spirochete | 16Mn480X126X6 | YX and Homemade | ||||

Discharge outlet | 400×120 | YX and Homemade | ||||

Water pump section | Submersible slurry pump | 65ZJQ20-20-4 | units | 2 | YXhe Customization | |

Water pump connection component | standard configuration | set | 2 | YX and Optimal Selection | ||

Water pump hanger | standard configuration | set | 2 | YX and Homemade | ||

chain block | 1T | units | 2 | YX and Optimal Selection | ||

Water pump frame | standard configuration | number | 2 | YX and Homemade | ||

pipe fitting | Add water pipe | DN65Galvanized pipe | meter | several | YX and Optimal Selection | Determine according to the plan |

Flushing pipe | DN65Galvanized pipe | meter | several | YX and Optimal Selection | ||

electrical system | controller | PLC | units | 1 | Siemens | |

AC contactor | LC1Dseries | units | 4 | chint | ||

Motor circuit breaker | GV2MEseries | units | 4 | chint | ||

MCCB | 125A and so on | units | 1 | chint | ||

Button/knob | number | 4 | YX and Optimal Selection | |||

pilot lamp | number | 3 | YX and Optimal Selection | |||

Control cabinet | Waterproof type | number | 1 | YXhe Customization | ||

Intermediate relay | 220V | set | 1 | chint | ||

Warning lights | number | 1 | YX and Optimal Selection | |||

cable | national standard | meter | several | YX and Optimal Selection | ||

attachment | national standard | number | several | YX and Optimal Selection | ||

Button box component | box | 300*200 | number | 1 | YX and Optimal Selection | |

Button/knob | number | 2 | chint | |||

bracket | number | 1 | YX and Homemade | |||

lubrication system | automatic lubricating pump | 4-2-AC220 | Determine according to the plan | |||

cable | cable | 3*2.5 | meter | 30 | YX and Optimal Selection | Determine according to the plan |

attachment | attachment | set | 1 | YX and Optimal Selection | ||

Note: The specifications/features, quantities, etc. listed in the table are standard configuration related parameters, and actual parameters may change due to changes in specific plans. As a component of zero sewage discharge, the electrical system is deployed in the same system as the zero sewage discharge control system. | ||||||