Product Introduction

Equipment performance characteristics and advantages

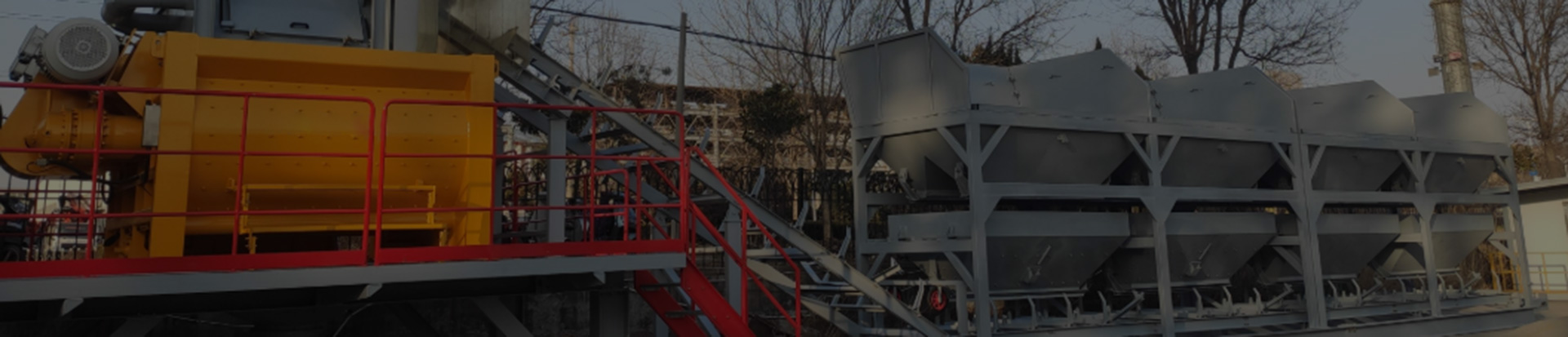

YX60D vibrating sand and gravel separator (vibrating motor type): It is a product specially designed by our company for the recycling of concrete sand and gravel materials in the concrete industry. The industry standard for the inspection of this equipment is "Recycled Light and Coarse Aggregates from Construction Waste for Concrete" (Plan No. 2020-0457T-JC).

This sand and gravel separator is a commonly used type of sand and gravel separator today, using dual 1.5KW (2.2KW for dual parking spaces) vibration motors as power sources. The working principle is that the vibration motors provide vibration sources, and the tank truck flushing sewage is poured into the separator's guide pool. The separator filter separates the stones and fine sand, and the fine sand and sewage are screened out and leaked into the low-end screw. Through the rotation of the screw, the fine sand is exported out of the separator, and the stones fall into the stone storage pool with the vibration of the vibrating screen, so that the stones and fine sand are completely separated, achieving the purpose of secondary use.

The screening capacity of YX60D vibrating sand and gravel separator is ≥ 60 tons/H, which can meet the separation task of 50 vehicles passing through the mixing plant; The size of the stone separator is ≥ φ 5mm, and the size of the powder sand is ≤ φ 5mm. The control system meets the functions of fully automatic, manual, and one key start. It is a mature technology, stable and reliable concrete recycling equipment.

The control method is designed as PLC control, and the PLC control system is Siemens brand, which meets the functions of fully automatic, manual, and one key start; The electrical components use Schneider brand, and the use of these branded electrical components greatly improves the operational reliability of the sand and gravel separator. This YX60D vibrating sand and gravel separator is an essential concrete recycling and environmental protection equipment for concrete mixing plants.

Technical Parameters

Project | Parameters | Notes |

model | YX60D(single-unit) | YX60DS(dual position) |

Screening capacity | ≥50T/H | ≥60T/H |

Screening capacity | ≤50 units | ≥50 units |

External dimensions (MM) | 7200*1800*3000(Length/Width/Height) | 9200*1800*2600(Length/Width/Height) |

Screen size (MM) | 4000*1500(Length * Width) | 6000*1500(Length * Width) |

Stone size division | ≥φ5 MM | ≥φ5 MM |

Sand size division | ≤φ5MM | ≤φ5 MM |

Whole machine power | 14.5KW | 15.9KW |

Whole machine weight (KG) | 4000KG | 4800KG |

Configuration of YX60D vibrating separator

Name | Specification/Feature | unit | quantity | Supporting manufacturers | notes | |

Vibrating chute section | Material tank body | T4-T8 | set | 1 | YXhe's self-made | |

rack | 100x50Square tube | YXhe's self-made | ||||

sieve plate | steel wire gauze 8*8mm | Hebei | ||||

Rinse tube group | Galvanized pipe | YX | ||||

Bumper | 120*100 | piece | 8 | YXhe's select | ||

Vibration motor | 1.5KW-Level 6 | unit | 2 | Debon Machinery | dual position2.2KW-6 | |

Sand extractor section | Reducer | PK07Hard tooth surface | set | 1 | Jiangsu Tailong | |

electrical machinery | 5.5KW | Jiangsu Tailong | ||||

structure | T5 | YXhe's self-made | ||||

spirochete | 16Mn | YXhe's self-made | ||||

Discharge outlet | 400×150 | YXhe's self-made | ||||

Water pump section | sewage pump | 3KW | unit | 2 | YXhe's self-made | |

Water pump connecting component | standard configuration | set | 2 | YXhe's select | ||

Water pump hanger | standard configuration | set | 2 | YXhe's self-made | ||

chain block | 1T | unit | 2 | YXhe's select | ||

Water pump frame | standard configuration | piece | 2 | YXhe's self-made | ||

pipe fitting | Add water pipe | DN65Galvanized pipe | meter | several | YX | |

Flushing pipe | DN65Galvanized pipe | meter | several | YX | ||

electrical system | controller | PLC | unit | 1 | Siemens | |

AC contactor | LC1D series | unit | 4 | schneider | ||

Motor circuit breaker | GV2ME series | unit | 4 | schneider | ||

Molded case circuit breakers | 125A, etc. | unit | 1 | schneider/CHINT | ||

Buttons/knobs | piece | 4 | CHINT | |||

indicator light | piece | 3 | CHINT | |||

control cabinet | Stainless steel waterproof type | piece | 1 | YXhe's self-made | ||

Intermediate relay | 220V | set | 1 | schneider/Omron | ||

warning light | piece | 1 | YXhe's select | |||

Cables | National Standard | meter | several | Yanggu Cable | ||

appendix | National Standard | piece | several | YXhe's select | ||

Button box assembly | Cabinet | 300*200 | piece | 1 | YXhe's select | |

Buttons/knobs | piece | 2 | schneider/CHINT | |||

bracket | piece | 1 | YXhe's self-made | |||

Lubrication system | Automatic lubrication pump | 4-2-AC220 | YXhe's self-made | |||

Cables | cable | 3*2.5 | meter | 30 | Yanggu Cable | |

appendix | appendix | set | 1 | YXhe's select | ||

Note: The specifications/features, quantities, etc. listed in the table are standard configuration related parameters, and actual parameters may change due to changes in specific plans. As a component of zero sewage discharge, the electrical system is deployed in the same system as the zero sewage discharge control system. | ||||||