Product Introduction

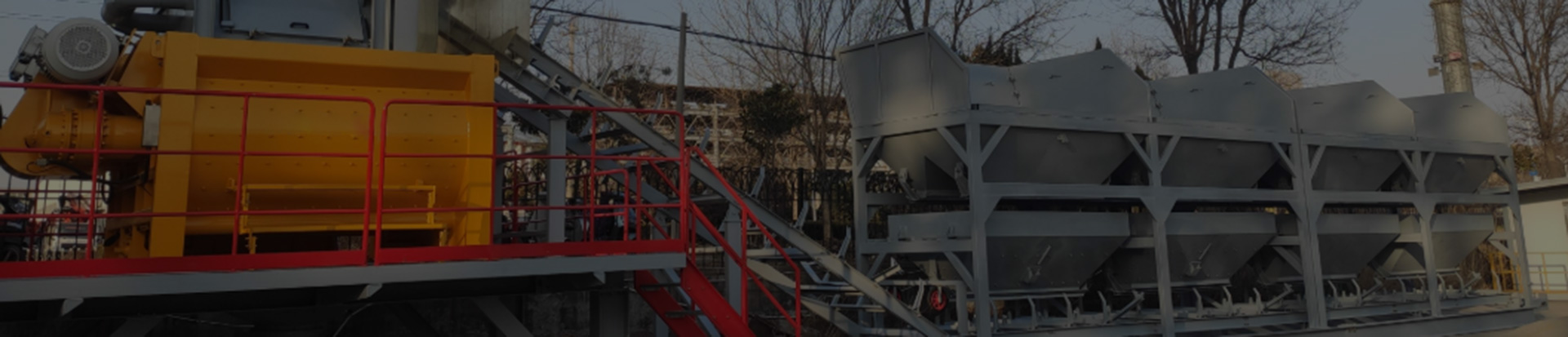

The YX40 drum type sand and gravel separator is an environmentally friendly product designed and developed by our company's researchers based on the absorption and reference of advanced technologies at home and abroad, and according to China's national conditions.

This product has a compact structure and a spacious effective working area, which can accommodate the unloading and cleaning work of one or two mixing trucks according to the situation.

This device is mainly used for cleaning concrete mixer trucks and pump trucks, as well as separating and recovering sand, stones, and sewage from residual wet concrete for reuse.

To avoid blockage during feeding, high-pressure water flow is used for feeding in the hopper machine section. The use of this method ensures that materials can be evenly and cleanly fed into the separation system, avoiding the system from being overloaded at any time and reducing the labor intensity of workers. After the work is completed and the set time is reached, the clear water that has been precipitated in the separator will be automatically discharged, and the separator drum will be cleaned to prevent clogging of the sieve holes.

We have completely solved the pollution problem of waste concrete, and our company also provides the design and installation of sewage reuse systems. This series of equipment includes sewage mixers, sewage recovery systems, etc.

Structure and Principle

This set of environmental protection equipment mainly consists of three parts: separation system, water supply system, and electrical control system.

The concrete mixer truck is poured into the car washing platform for cleaning, and the cleaned waste is poured into the material tank machine. The waste material is pushed into the drum of the separator by high-pressure water flow for cleaning and separation. The separated stones and sand are directly discharged through the stone outlet and sand outlet, and then transported away by loading equipment and other material handling devices. The mud overflowing from the drainage outlet settles step by step before flowing into the clean water tank.

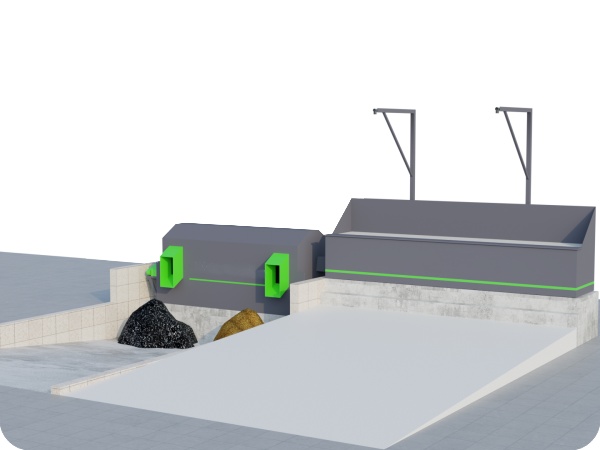

The schematic diagram of the process flow is as follows:

1. Separation system

The separation system is the main part of this equipment, which mainly consists of a hopper machine and a separator.

The waste in the hopper machine is flushed into the separator by high-pressure water flow.

The drum of the separator is driven by a reduction mechanism to rotate for screening.

The overflow slurry is discharged into the sedimentation tank through the drainage outlet for step-by-step sedimentation. Then it flows into the clean water tank.

2. Water supply system

The water used during the operation of this device mainly consists of the following two parts:

A. Add water to the mixer truck.

B. Equipment cleaning and separation water.

The sources of water can be divided into:

A. The clean water supplied by the water supply station.

B. Clear water separated from the equipment and precipitated.

The water supply system mainly consists of water stations, water pumps, water pipelines, etc.

Except for the water supply pipelines installed inside the equipment, the water supply pipelines around the equipment are the responsibility of the user and installed according to the actual situation on site!

3. Electrical control system

The main electrical components are made of Schneider brand, ensuring the safety, stability, and reliability of the control system. The model configuration and control principle of the electrical components are detailed in the electrical schematic diagram of the concrete cleaning and separating machine.

4.Installation and debugging

1. Installation (refer to the foundation diagram layout):

a. Install and arrange the separator and hopper machine in order; Ensure that the discharge port bearing of the hopper machine is in contact with the drum cover of the separator.

b. The electrical control cabinet needs to be equipped with grounding protection devices. The grounding resistance should be ≤ 4 Ω. The grounding terminal should be reserved by the user during the foundation construction and installed on site.

2. Debugging: Before trial operation, pay attention to whether there are foreign objects, debris, etc. inside the equipment!

1) Manually operate each motor to confirm if the rotation direction is correct and if the water pump output is normal.

2) Run for a certain amount of time, observe whether there is any abnormal noise from the equipment, and whether there is any abnormal tripping of the switches inside the cabinet.

3) The debugging method can refer to the manual operation method.

If any abnormal phenomenon is found, stop the machine immediately! Find out the cause and eliminate the fault before restarting! After the machine is tested again and normal, the next operation can be carried out.

Technical Parameters

Model | Screening Capacity | Total Weight | Sand Separation Size (MM) | External Dimensions Length * Width * Height (MM) | Whole Machine Power (KW) | Number of Mixer Yrucks |

JGF40 (Single parking space) | ≥30T | 3500KG | diameter1-6 | 4500*1800*1750(Host) | 11.5KG (including water pump) | ≤20tower |

YX40 Drum Separators Configuration Table

Name | Specifications/Features | Unit | Quantity | Supporting Manufacturers | Remark | |

Separator host | motor | YX3-160M2-8 | set | 1 | Boshan Xiangze | |

reducer | JZQ400, hardened tooth surface | Rongcheng Huayu | ||||

Spiral drum | T4 manganese steel-1400 | YX Homemade | ||||

Spirochete | T6 manganese steel-10 | |||||

Shaft end seal | Wear-resistant castings | |||||

guide chute | T4 hot rolled plate/coil | |||||

Flushing components | DN65 | |||||

Water pumps and components | Sewage submersible pump | 80WQ40-15-3kw | tower | 1 | YX Customization | Three-compartment non-clogging submersible electric pump |

Sewage submersible pump | 80WQ40-15-3kw | tower | 1 | YX Customization | ||

Pump connection kit | Standard | set | 2 | YX Optimum | ||

Water pump hanger | Standard | set | 2 | YX Homemade | ||

Pump lifting equipment | 1T | tower | 2 | YX Optimum | ||

pipe fittings | Water pipe | DN65PVC/galvanized pipe | rice | several | YX Optimum | Determined according to the plan |

flushing tube | DN65PVC/galvanized pipe | rice | several | YX Optimum | ||

pipe fittings | DN65 | indivual | several | YX Optimum | ||

electrical system | Controller | Relay/PLC | tower | 1 | Delixi/Siemens | |

AC contactor | NXC series | tower | 3 | Delixi/Chint | ||

Motor circuit breaker | NS2 series | tower | 3 | Delixi/Chint | ||

Molded case circuit breakers | 125A, etc. | tower | 1 | Delixi/Chint | ||

Buttons/knobs | indivual | 3 | YX Optimum | |||

indicator light | indivual | 3 | YX Optimum | |||

control cabinet | Waterproof | indivual | 1 | YX Customization | ||

Intermediate relay | 220V | set | 1 | Delixi/Chint | ||

warning light | 220V | indivual | 1 | YX Optimum | ||

Cables | National Standard | rice | several | YX Optimum | ||

appendix | National Standard | indivual | several | YX Optimum | ||

Button box assembly | Cabinet | 300*200 | indivual | 1 | YX Optimum | Optional |

Button | indivual | 2 | Chint | |||

bracket | indivual | 1 | YX Homemade | |||

Cables | cable | 3*2.5/1.5 | rice | 30 | YX Optimum | Determined according to the plan |

appendix | appendix | set | 1 | YX Optimum | ||

Note: The specifications/features, quantities, etc. listed in the table are standard configuration related parameters, and actual parameters may change due to changes in specific plans. As a component of zero sewage discharge, the electrical system is uniformly deployed in the zero sewage discharge control system. | ||||||