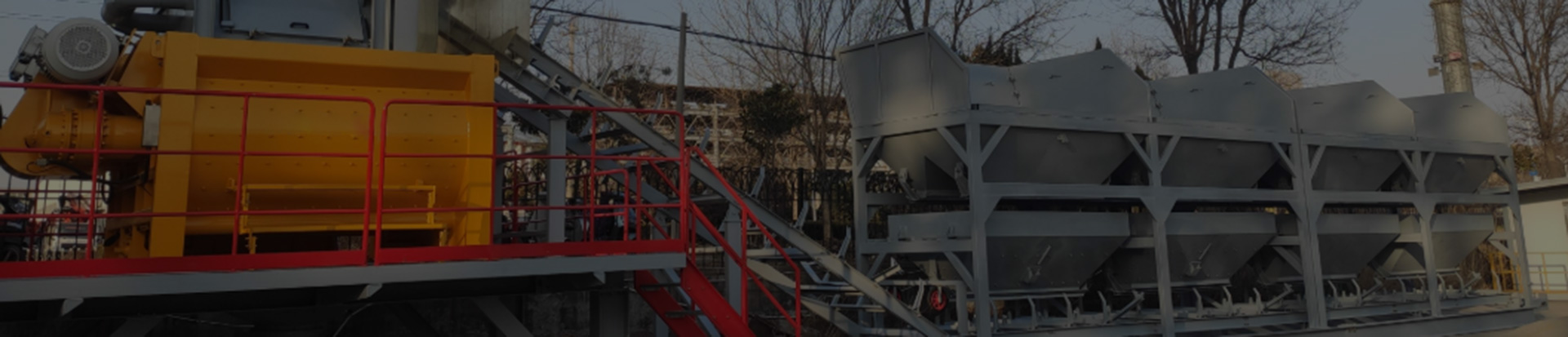

Product Introduction

Equipment performance characteristics and advantages

The structure is simple and compact, with strong operational continuity, and has been in use in the market for nearly 30 years. Currently, many engineering stations are still in use.

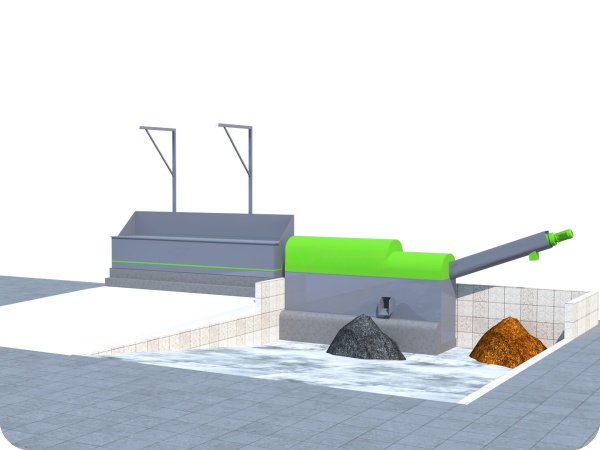

The main body of the separator is divided into two parts: the separation host part and the guide chute part. The guide chute can be designed as a single or double parking space according to user needs.

To avoid blockage during feeding, high-pressure water flow is used in the feeding trough machine to ensure that the material can be evenly and cleanly fed into the separation system, avoiding overloading of the separation system at any time and reducing the laborintensity of workers.

After the separation work is completed, the clear water that has been precipitated in the separator will be automatically discharged, and the separator drum will be cleaned to prevent clogging of the sieve holes.

Technical Parameters

Name | Single-Unit | Dual-Unit |

Screening Capacity | ≥30T/H | ≥40T/H |

Separation Cylinder Specifications | φ1500*3400 MM | φ1500*3400 MM |

Host Size | 4500*1800*1750 MM | 4500*1800*1750 MM |

Discharge Hopper Size | 3000*900 MM | 6000*900 MM |

Stone Size Division | ≥Φ5 MM | ≥φ5 MM |

Sand Size Division | ≤φ5 MM | ≤φ5 MM |

Nhole Machine Power | 13 KW | 16KW |