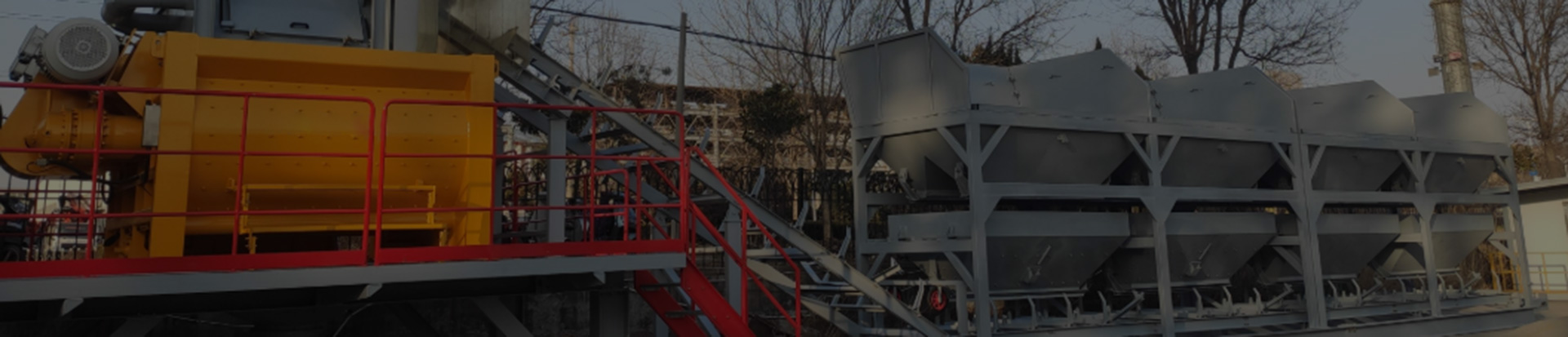

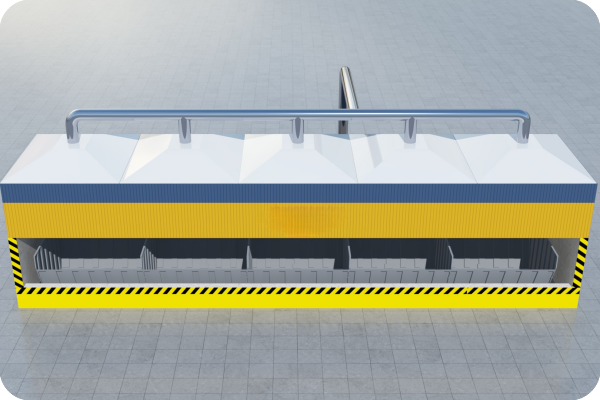

Step 1: The concrete mixer truck drives onto the car wash platform. The tanker driver or operator presses the start button, and the separator begins operation: the tanker automatically adds water for cleaning, and the water addition automatically stops according to the set parameters.

Step 2: Operate the mixer truck to pour the waste material cleaned from the tank into the trough.

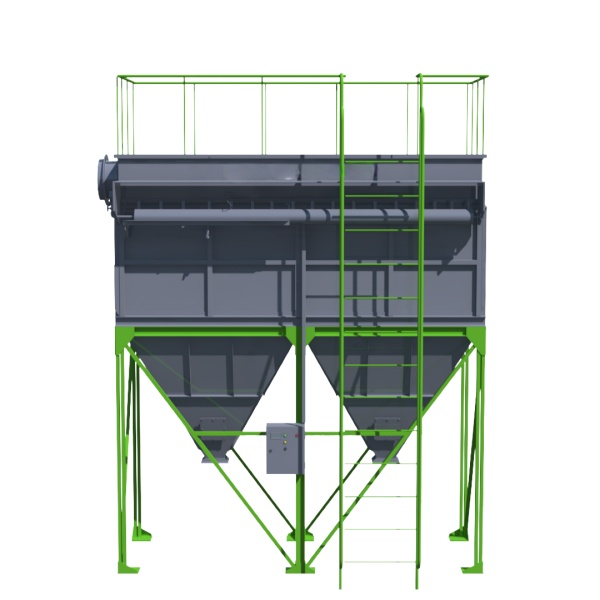

Step 3: The waste material enters the separator, where it is automatically cleaned and separated.

Step 4: The separated sand and gravel are pushed by the screw to the discharge port for direct discharge, where they are finally transported by a loader or other transport equipment.

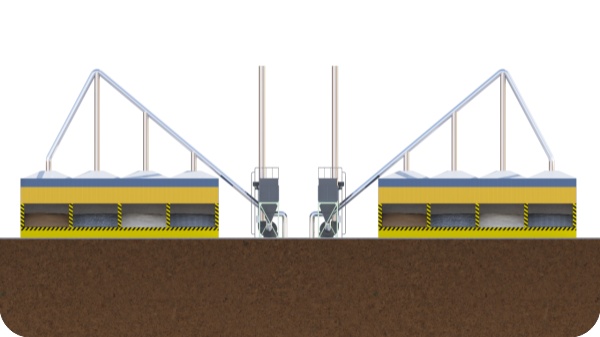

(1) At the same time, the muddy water overflowing from the discharge port of the separator enters the recirculation pool through the recirculation ditch. The sewage in the recirculation pool contains some fine sand to prevent the mud concentration from being too high. The sewage in the recirculation pool is pumped to the fine sand cyclone by the slurry pump. The fine sand treated by the fine sand cyclone is discharged to the sand discharge screw of the separator. The screw and the coarse sand are pushed to the discharge port for direct discharge.

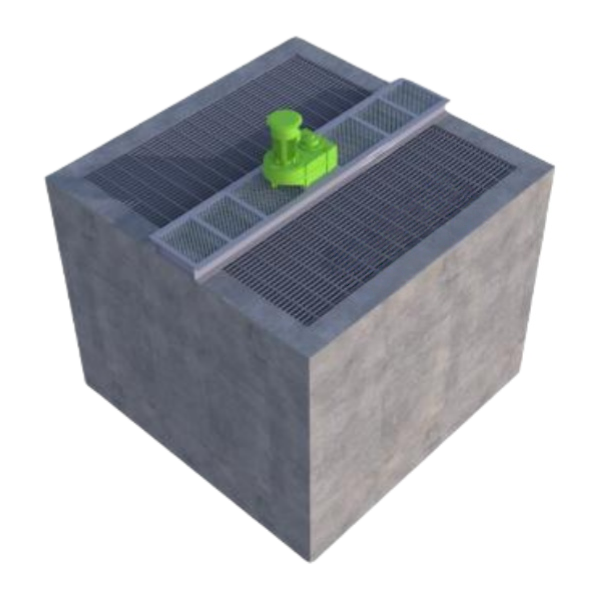

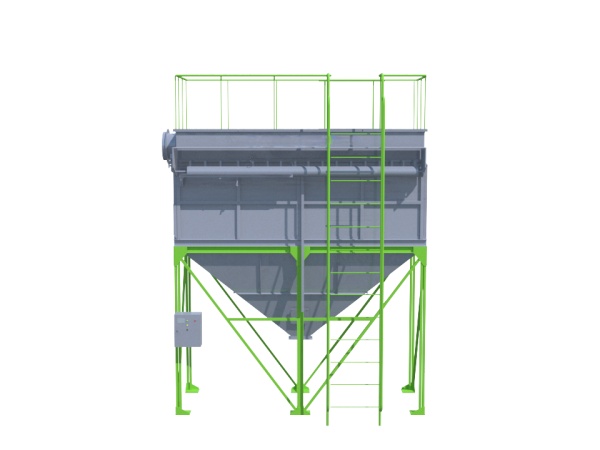

(2) The sewage separated by the cyclone enters the mixing tank. The separated sand and gravel contain some water and flow into the mixing tank after natural sedimentation.

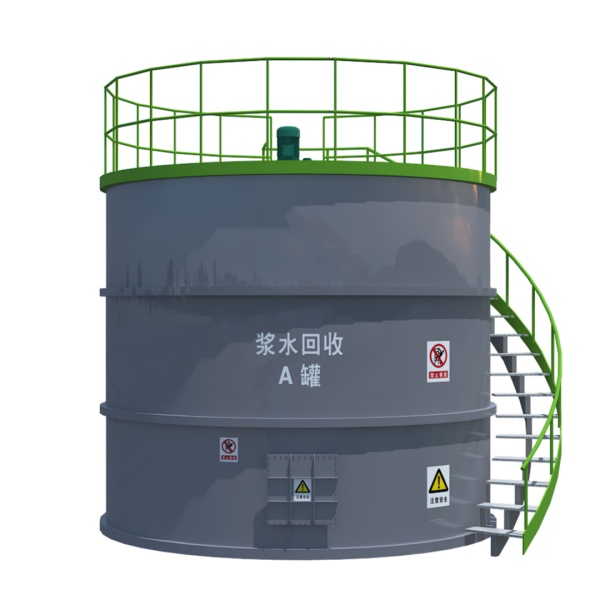

(3) The sewage in the mixing tank enters the sewage tank for compounding through the sewage pump. The sewage tank is equipped with an intermittent mixer to prevent sewage sedimentation and a three-level water level sensor. According to actual production needs and sewage concentration, clean water can be added according to the proportion for compounding to reduce sewage concentration. The compounded sewage is fed to the mixing station sewage scale for measurement through the sewage pump. The sewage tank is equipped with an overflow pipe to overflow into the mixing tank to avoid sewage pollution due to operational errors or mechanical failures. A sewage valve is provided at the bottom of the sewage tank to prevent sewage concentration from being too high.

(4) The wastewater in the mixing tank is flushed by tank trucks through the slurry pump pipeline. The mixing tanks are interconnected to avoid excessive wastewater or insufficient water supply caused by centralized car washing.

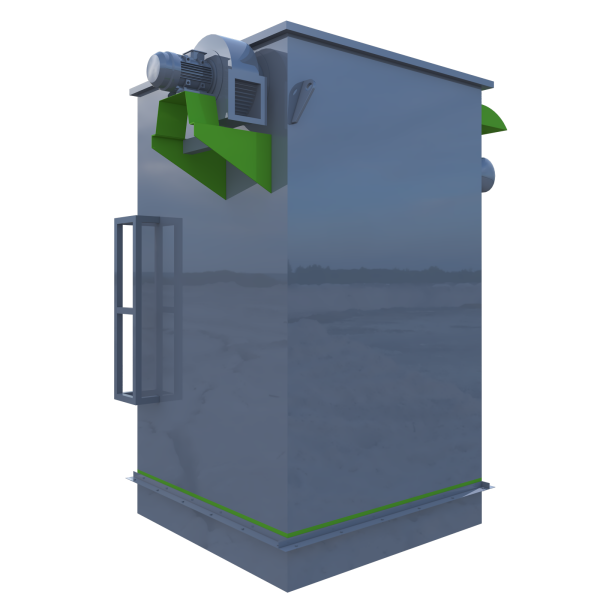

(5) In the actual production process, if the amount of wastewater is not large, to avoid the wastewater concentration in the mixing tank exceeding the standard, the wastewater in the mixing tank is pumped into the filter press through the slurry pump. The filter press filters the mud in the wastewater and compresses it into blocks under high pressure. The filtered clean water flows into the mixing tank, thereby reducing the wastewater concentration in the mixing tank to adapt to the concrete mix ratio of each grade, thereby ensuring normal production of the mixing station and reducing the operating frequency of the mixer.