Concrete equipment

Construction machinery

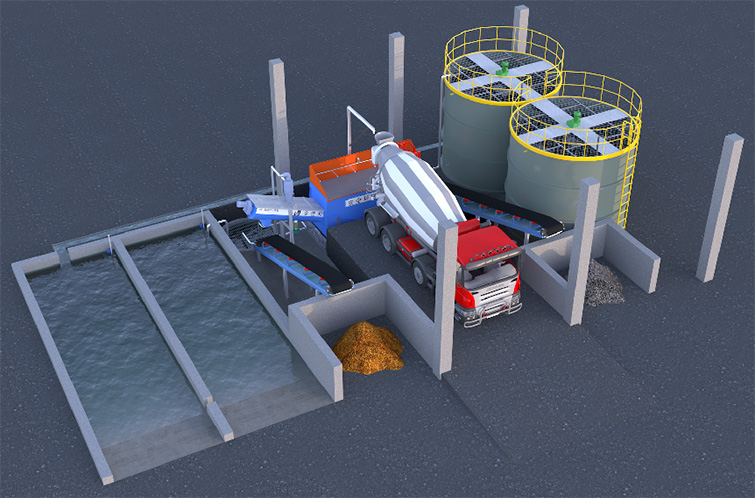

Step 1: The concrete mixer truck drives onto the car wash platform. The tanker driver or operator presses the start button, and the separator begins operation: the tanker automatically adds water for cleaning, and the water addition automatically stops according to the set parameters.

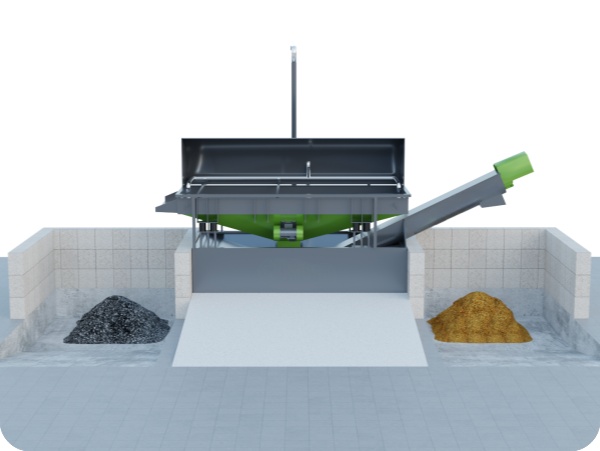

Step 2: Operate the mixer truck to pour the waste material cleaned from the tank into the trough.

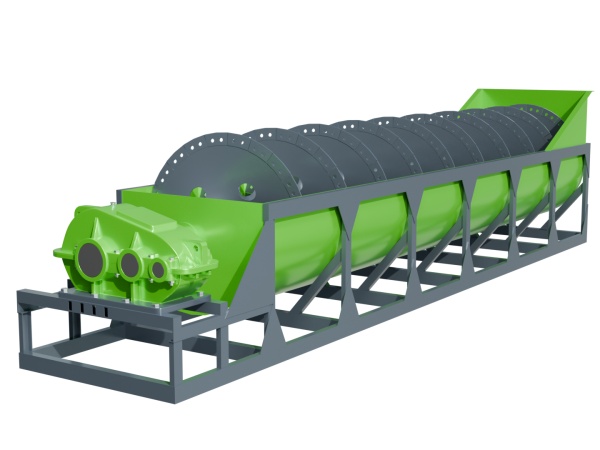

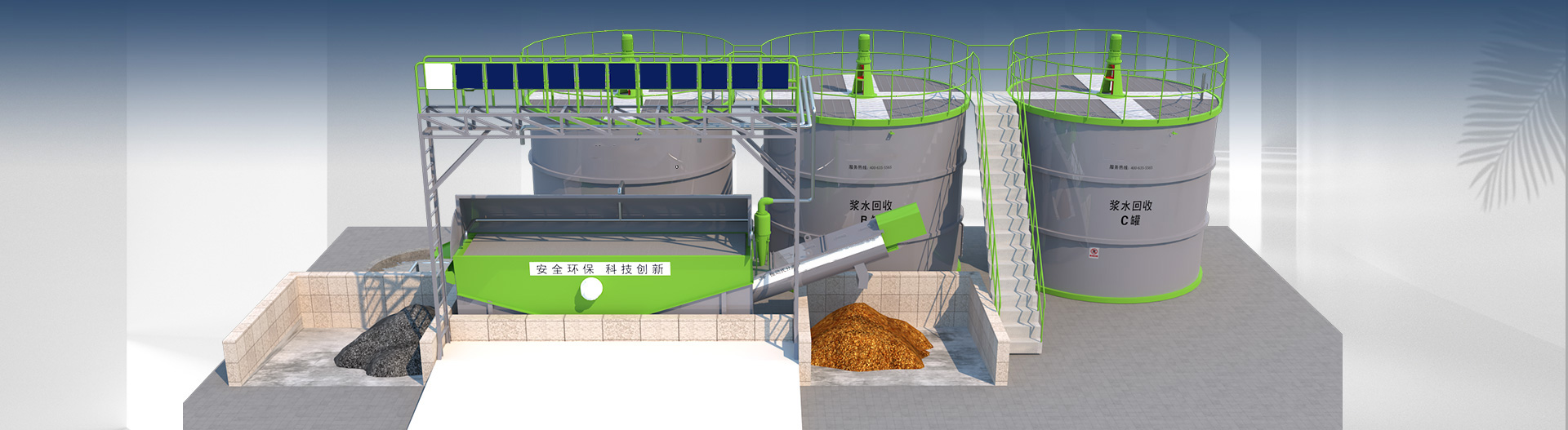

Step 3: The waste material enters the separator, where it is automatically cleaned and separated.

Step 4: The separated sand and gravel are pushed by the screw to the discharge port for direct discharge, where they are finally transported by a loader or other transport equipment.

(1) At the same time, the muddy water overflowing from the discharge port of the separator enters the recirculation pool through the recirculation ditch. The sewage in the recirculation pool contains some fine sand to prevent the mud concentration from being too high. The sewage in the recirculation pool is pumped to the fine sand cyclone by the slurry pump. The fine sand treated by the fine sand cyclone is discharged to the sand discharge screw of the separator. The screw and the coarse sand are pushed to the discharge port for direct discharge.

-

read more

Since taking root in Xuzhou, Jiangsu on October 12, 2011, Shandong YX Engineering Tech Co., Ltd has been forging ahead in the field of engineering machinery for more than ten years and is the core force of Xuzhou's engineering machinery industry cluster. We focus on the research and development of concrete equipment, maintenance and leasing of engineering machinery, and innovative application of environmental protection technology, shaping industry benchmarks with professional strength.

The company has a modern production base of 10000 square meters, relying on advanced production equipment and a professional technical team to carefully create efficient, energy-saving, and environmentally friendly solutions for the entire process of concrete production, with a service network covering the whole country. In response to the pain points of domestic mixing plant enterprise parts procurement, we have also established a large concrete mixing plant parts warehouse of more than 3000 square meters, gathering high-quality parts from multiple brands, ensuring complete categories, reliable quality, transparent prices, and providing efficient distribution services, fully solving problems for industry partners.

- 1. Carefully crafting efficient, energy-saving, and environmentally friendly solutions for the entire process of concrete production.

- 2. Service network covers the whole country

- 3. Complete categories, reliable quality, transparent prices

- 4. Provide efficient delivery services and spare no effort to solve problems for industry partners

- 5. Environmental Empowerment Manufacturing, Technology Driven Services

-

Jul 01, 2025

-

Jul 01, 2025

-

Jul 01, 2025